AOD® Ammonia on Demand is the Safest and Most Cost Effective Process for DeNOx

For small applications of up to approximately 30 lb/hr of ammonia, WAHLCO has developed a cost effective urea to ammonia system under the trademark: AOD® (Ammonia on Demand).

The technology offers a small packaged unit complete with urea feed pump, controls, ammonia production, and heated dilution air. All of the components are fully contained on one small skid to enable quick and easy installation.

Ammonia - The Hazards

Ammonia is typically used as a chemical agent for the reduction of nitrous oxide emissions (NOx). Anhydrous ammonia is a highly toxic chemical (subject to EPA, DOT, OSHA, and Dept. of Homeland Security regulations), which is typically stored in pressure vessels (rated to 300 psig) as a liquified-gas. There are significant risks and liability associated with its transport, unloading, and bulk storage.

For example, several trucks or railcars must be unloaded each day, so the potential risk is on-going. The resulting bulk storage requirement presents a significant hazard. In the event of a major storage tank failure, an ammonia aerosol cloud will form and travel several miles – with the potential to be immediately lethal.

It should be noted – aqueous ammonia, although less concentrated than anhydrous ammonia, poses similar risks and is increasingly subject to stricter regulations by local authorities.

New Regulations

New regulations require many industrial boilers and commercial combustion processes to be equipped with Selective Catalytic Reduction (SCR) of Nitrous Oxide Emissions. The SCR process typically utilizes injection of ammonia upstream of a catalyst to reduce the emissions to elemental nitrogen.

However, anhydrous ammonia, and to a lesser extent, aqueous ammonia, are highly toxic. To avoid the hazards of storage and handling of ammonia, many SCR systems utilize technology to convert non-toxic urea to ammonia on demand.

The AOD® Process

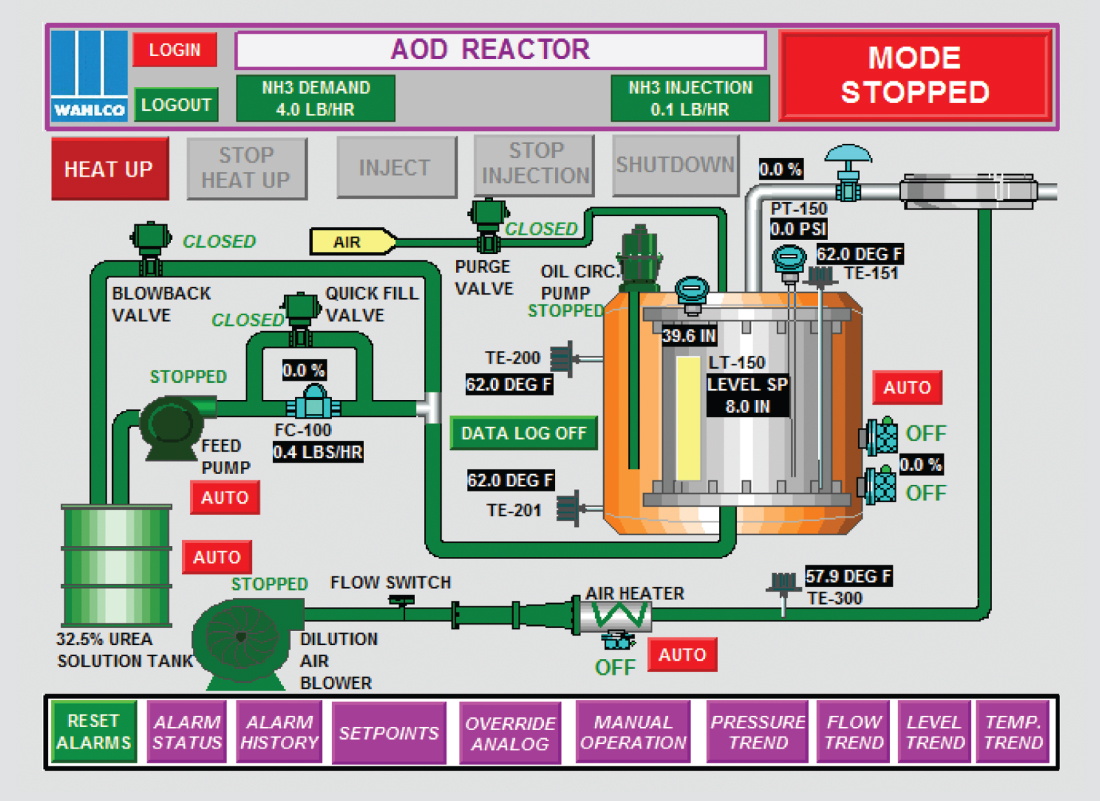

In the AOD® process, urea solution of 32.5% to 40% Diesel Exhaust Fluid (DEF) is supplied from a small feed tank to a reactor and heated under pressure to produce a product gas stream of ammonia, carbon dioxide, and water vapor. The product gas is then mixed with heated air supplied from an electric heater on the unit and routed to the injection grid upstream of the SCR unit.

Fully Automated Control by PLC or Plant DCS

Product Description

The skid mounted AOD® system has the following specifications:

- Skid dimensions: from 6′ to 9′ L x 4′ to 6′ W x 7′ to 8′ H (depending upon capacity)

- Dry weight: 4,000 lb, operating weight 5,200 lb

- Heat transfer oil shipped separately in drums (130 gal., 1,200 lb)

Product Performance

- Sized for up to 30 lb/hr of ammonia

- Product gas is 5% ammonia maximum by volume

- Ammonia delivery/discharge time from hot stand-by: 3 minutes

- Utilities:

- Electric power: 480VAC, 3-phase, 60 Hz, 25 to 60 kW

- Instrument air: 3 cfm at 85 psig

- Noise level: less than 85 dBA

Markets

Small Industrial Boilers

- Airports

- Cogen facilities

- Correctional facilities

- Food processing

- Hospitals

- Hotels / resorts

- Independent power producers

- Laundry / dry cleaning facilities

- Oil and gas

- Pulp and paper

- Universities