Flue Gas Conditioning Systems

Flue Gas Conditioning is WAHLCO’s traditional core business and the product line which formed the basis of the company’s founding. FGC systems allow coal fired boilers to burn a wider variety of coals, including lower cost high ash coals and low sulfur coals which avoid the cost of scrubber installations, without affecting the performance of the fly ash particulate collectors (electrostatic precipitators).

Regulatory Requirements

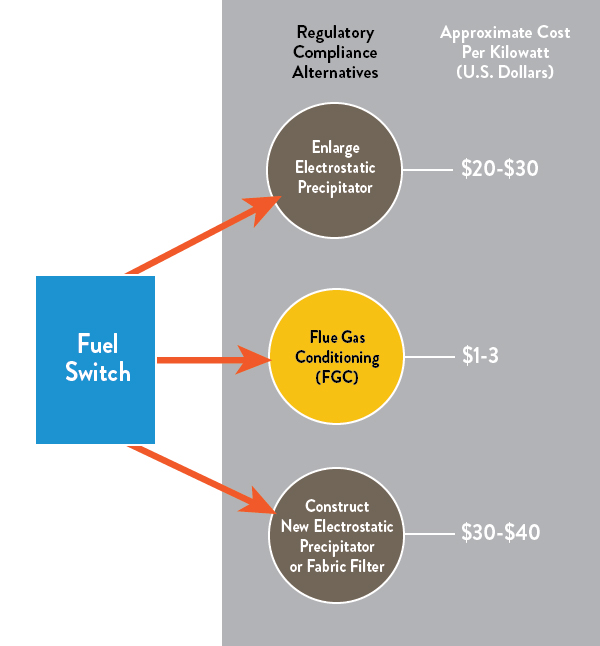

FGC is important, in some cases mandatory, where utilities have switched to burning low sulfur coal to meet required sulfur dioxide emissions. The burning of low sulfur coal reduces the efficiency of the associated electrostatic precipitators (ESP) which collect the ash from coal fired boilers. The implementation of FGC restores the performance of the ESP to design and in many cases provides significant particulate collection efficiency improvement.

Many utilities are changing hands, as a result of deregulation and mergers, and these new owners are likely faced with increasingly stringent requirements for the reduction of sulfur dioxide emissions. In most cases, utilizing low sulfur coal in combination with FGC is the most cost effective strategy to achieve required compliance with sulfur dioxide emissions requirements.

What Is Flue Gas Conditioning?

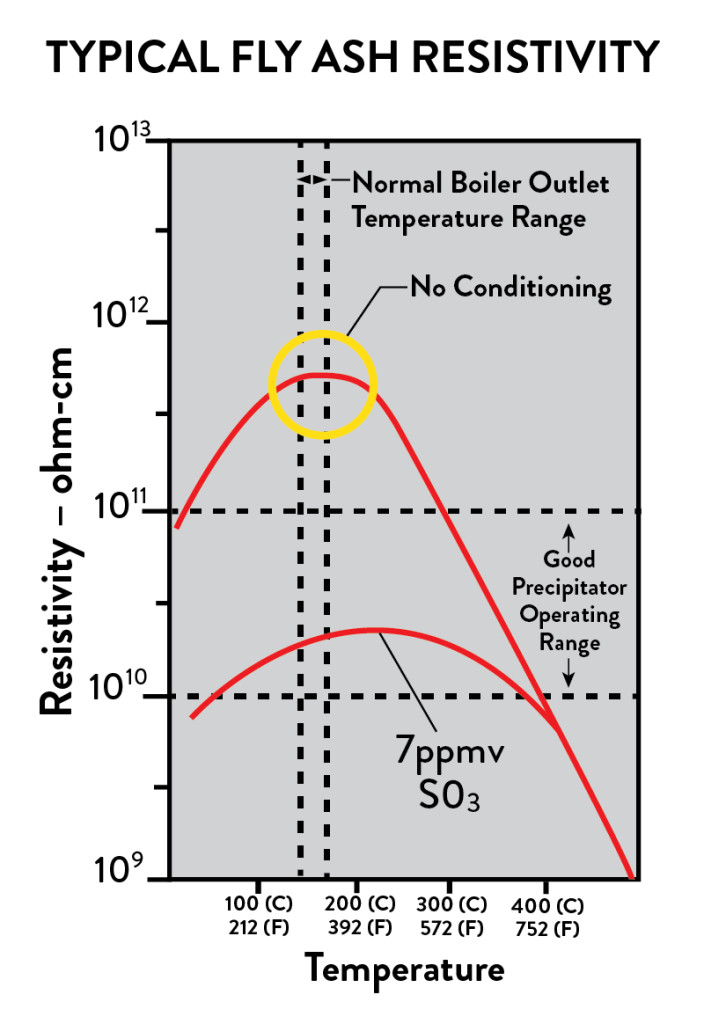

Flue Gas Conditioning is the controlled injection of small quantities of sulfur trioxide into the flue gas stream, reducing the resistivity of the fly ash and permitting its collection in the existing precipitator. When flue gas conditioning is installed on units that have switched to low sulfur coal, sulfur oxide emissions are significantly reduced, complying with environmental regulations and utility standards.

Why is Flue Gas Conditioning Needed?

Burning coal to produce electricity causes the emission of sulfur oxides such as sulfur dioxide and sulfur trioxide, or acid gas. This gas is carried into the atmosphere, along with fly ash generated from the combustion of the coal. When these acid gases combine with moisture in the atmosphere, they form dilute solutions of sulfuric acid or “acid rain” which fall back to earth, harming the environment.

High sulfur coal has traditionally been the standard fuel for coal-fired boilers and the fly ash produced from this fuel is readily collectable in electrostatic precipitators. Regulations restricting sulfur dioxide emissions are being implemented worldwide. In an attempt to comply with these new limitations, the power industry has begun the switch to lower sulfur coals. Low sulfur coal tends to generate more fly ash and flue gas per megawatt. Because of the higher resistivity of this ash, it is difficult to collect in existing precipitators.

Two solutions: 1) install much larger and more expensive precipitators or fabric filters for collection of the fly ash, 2) use a more cost-effective alternative, flue gas conditioning. Flue gas conditioning restores the collection efficiency of the precipitators to performance levels consistent with the firing of high sulfur coal.

WAHLCO offers a wide variety of methods to create sulfur trioxide for injection, each suited to varying utility applications. Additionally, we supply systems to inject ammonia, which either by itself or in combination with sulfur trioxide, provides unique solutions to particularly difficult fly ash collection problems.

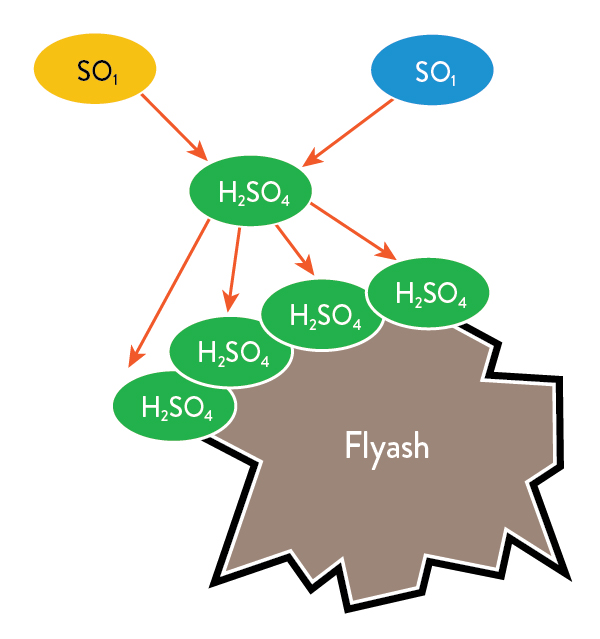

SO3 and moisture combine to form sulfuric acid, which is deposited on the fly ash surface, forming a conductive film and lowering the electrical resistance of the ash.

Regulatory Compliance Alternatives

Why Inject Sulfur Oxides?

It’s a common question. The answer lies in the difference between sulfur dioxide and sulfur trioxide. When high sulfur coals are burned, they yield large quantities of SO2 but very small amounts of SO3.

SO3 however, is very important, because it naturally combines with moisture in flue gas to create sulfuric acid. Sulfuric acid (H2 SO4) is deposited on fly ash particles to form a thin conductive film which lowers the electrical resistance of the ash, allowing it to be readily collected by electrostatic precipitation.

When low sulfur coals are burned, naturalSO3 levels are reduced to the point that they no longer can create enough H2 SO4 to properly “condition” the fly ash and reduce its resistivity. High resistivity ash passes through precipitators sized for high sulfur coal, creating unacceptable emissions.

Sulfur trioxide FGC systems, as developed and patented by WAHLCO, injects small quantities of SO3 into the gas stream. This newly introduced SO3 reacts in the same way as naturally-occurring SO3, lowering ash resistivity, and allowing easy collection.

Typical Sulfur Oxide Emissions from Coal-Burning Boilers