Aqueous Ammonia Delivery System: A Safer Alternative to Anhydrous Ammonia.

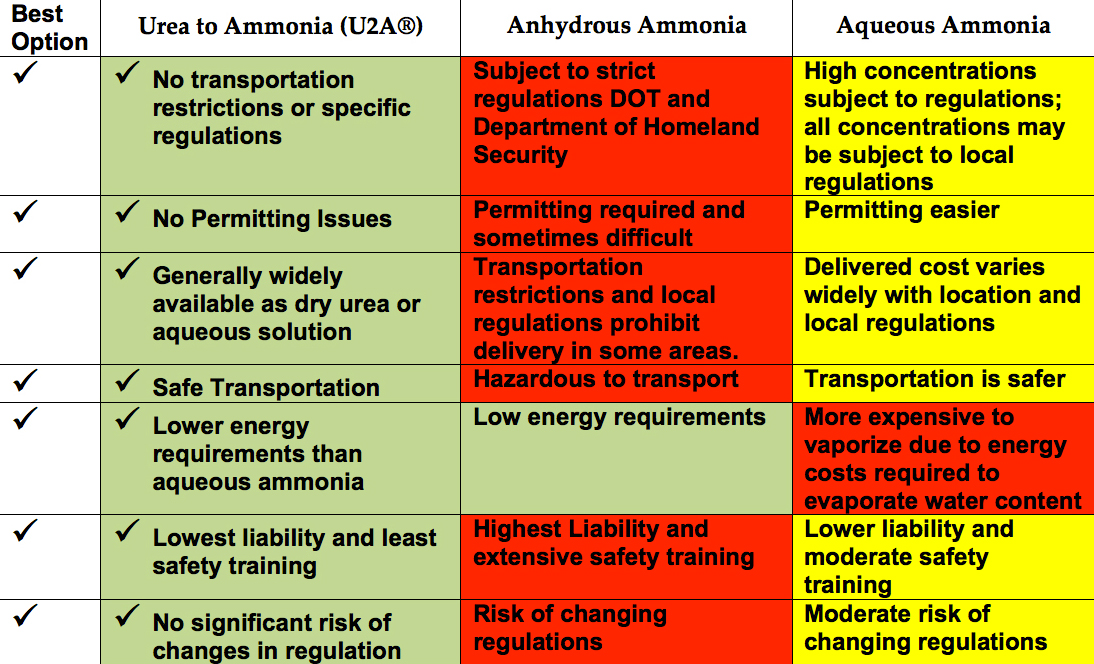

Aqueous Ammonia is a safer ammonia reagent for SCR applications than anhydrous ammonia; however it is more expensive on a delivered basis due to the large amount of water transported. Additionally in the case of 19% aqueous ammonia, there will be approximately five times as many deliveries as anhydrous ammonia. Operating costs are also higher due to the energy required to vaporize the water.

Ammonia Overview

Ammonia reagent is typically supplied as commercial grade anhydrous ammonia or aqueous ammonia. Anhydrous ammonia is significantly less expensive for SCR applications; however, aqueous ammonia is often specified due to permitting and safety considerations in transport, storage and handling. Commercial grade anhydrous ammonia is 99.5 – 99.7% pure, with a minimum of 0.3% water content. Aqueous ammonia or ammonia hydroxide can be specified and purchased over a range of ammonia contents.

Typically, aqueous ammonia is specified at concentrations of 19%, 25%, or 29% pure ammonia in water. Due to the additional cost, typically 4 – 5 times as expensive (on a basis of weight of pure ammonia) as anhydrous ammonia, and the additional cost of transport and storage of the water content, aqueous ammonia is used only when anhydrous ammonia is not a viable option. Aqueous ammonia normally requires more power resulting in higher operating cost.

Products & Services

- Aqueous Ammonia Vaporizers

- Heated Air or Hot Air

- Electrical Heaters

- Hot Flue Gas

- Steam

- Unloading Systems

- Truck

- Rail Car

- Storage Tanks & Accessories

- Forwarding / Feed Pump Skids

- Ammonia Flow Control Units (AFCU’s)

- Ammonia Injection Grids (AIG’s)

- Design & Fabrication

- Full Turnkey Systems

- Start-Up Maintenance Services

- O&M and Safety Training

Aqueous vs. Anhydrous Ammonia

Aqueous NH3 Systems

WAHLCO Aqueous Ammonia Delivery Systems use two types of vaporizers to generate ammonia; Hot Air and Steam Heated.

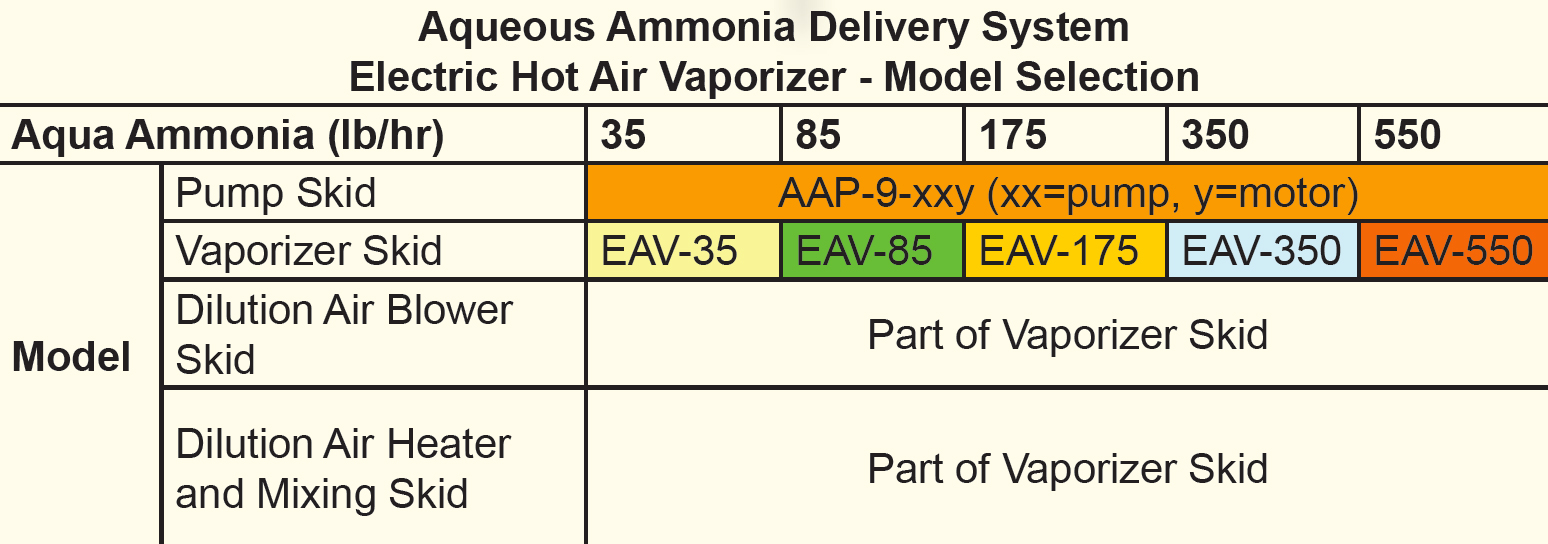

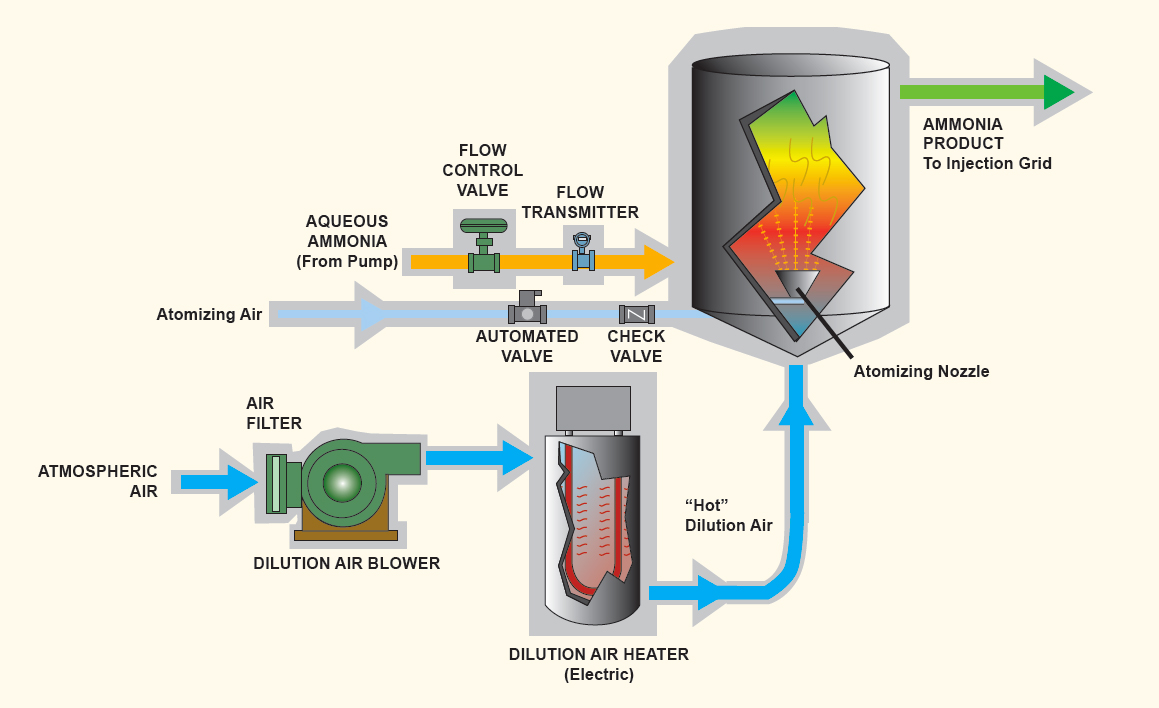

Hot Air vaporizers use an evaporative-type vaporizer with internal air atomizing nozzles. In operation, aqueous ammonia is pumped into the atomizing nozzle at a fixed pressure. Within the nozzle, the liquid is mixed with atomizing air and dispersed into the vaporizing chamber as a fine mist. Heated air is forced into the chamber, which evaporates the mist. The resulting air, ammonia vapor and water vapor mixture is piped to the ammonia injection grid.

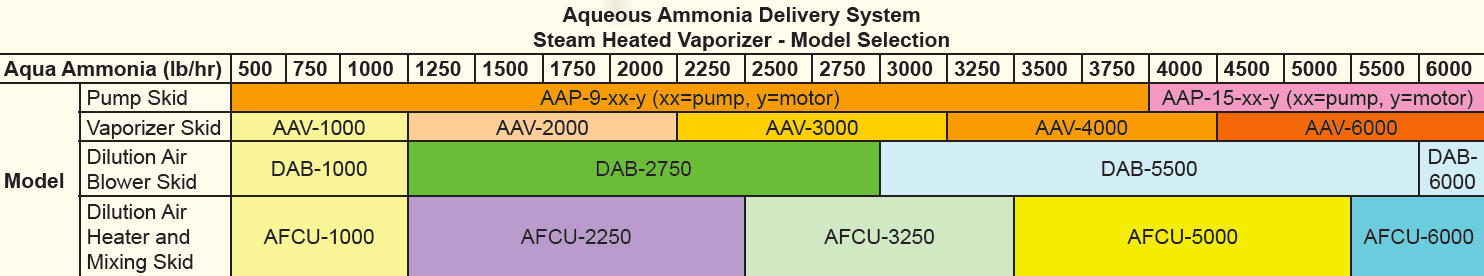

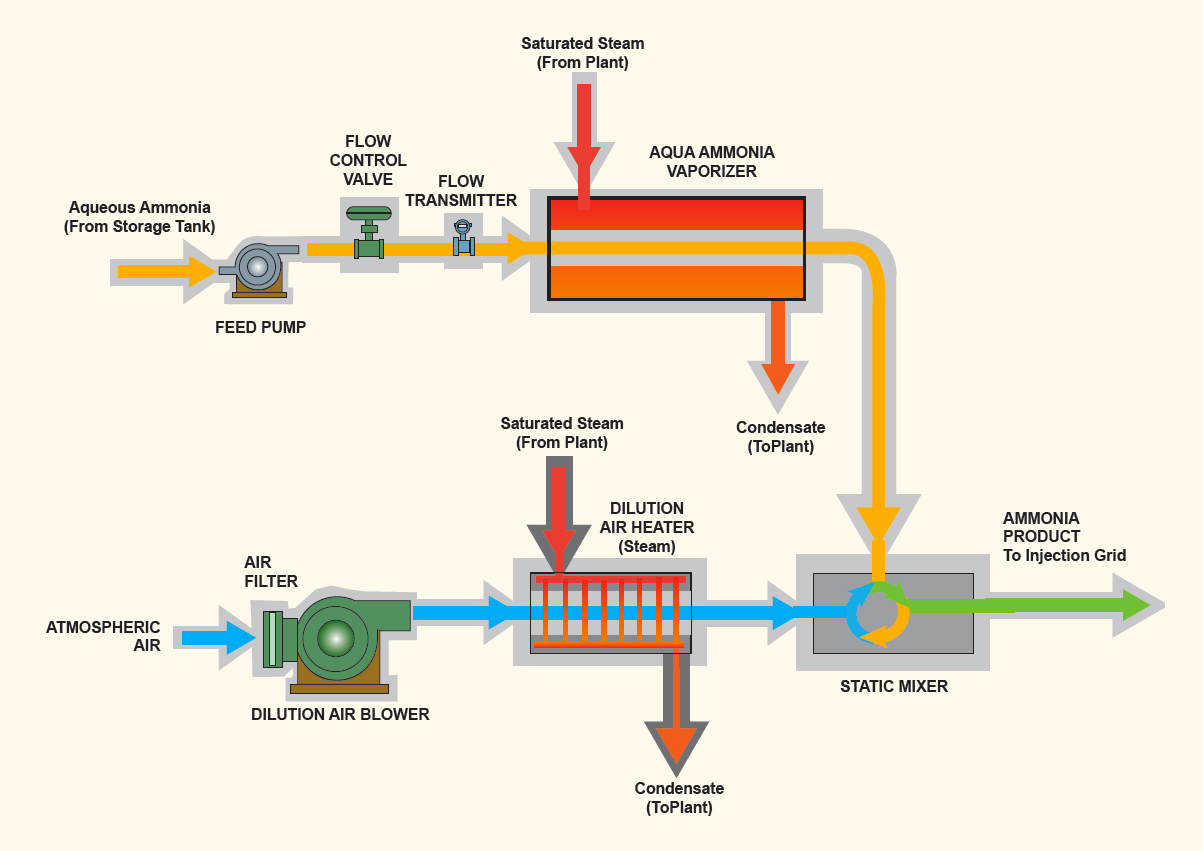

Steam Heated vaporizers use a shell and tube heat exchanger. During operation the vaporizer produces ammonia vapor, which is mixed (in a static mixer) with a fixed flow of heated dilution air. The resulting air, ammonia vapor and water vapor is piped to the ammonia injection grid.

Standardized Design

WAHLCO Aqueous Ammonia Delivery Systems are available in standardized models or custom designed systems. Standardized models offer pre-engineered, documented design based on proven technology and high quality components.

Standardized design packages reduce overall project time and costs since all P&IDs. Process Flow Diagrams, General Arrangement Drawings, component specifications, and standard calculations are already established.

- Reduced proposal preparation time

- Standardized documentation available immediately

- Shorter delivery schedule

- Less cost uncertainty

- Pre-engineered (fixed set of skid variations)

- Pre-selected components (no research time)

Electric Hot Air Vaporizer

- 20 to 550 lb/hr of Aqueous Ammonia

- Blower, vaporizer & AFCU on one skid

- For industrial & gas turbine applications

- 60 psig Aqueous Ammonia supply to vaporizer

- Maximum air heater output temp. of 650ËšF

- Dilution air volume based on vaporizer heat requirement (maximum of 2.5% ammonia concentration by volume after mixing)

- Dilution air heater inlet minimum temperature of -20ËšF and 250ËšF outlet temperature

- Dual fluid atomizing nozzle

Steam Heated Vaporizer

- 500 to 6,000 lb/hr of Aqueous Ammonia

- Steam vaporizer and air heater

- Multiple skids for installation flexibility

- For large utility applications

- 60 psig Aqueous Ammonia supply to vaporizer

- Vaporizer discharge to have 15ËšF superheat

- 150 psig saturated steam for vaporizer and air heater

- Dilution air volume based on 5% ammonia concentration by volume after mixing

- Dilution air heater inlet minimum temperature of -20ËšF and 250ËšF outlet temperature