Valve Train for a Wide Range of Applications

Fuel Skid / Valve Train Packages

WAHLCO designs and manufactures valve trains for applications servicing a wide range of industries including power generation, pulp and paper, refining and chemical processing. Our skids and valve trains are designed to meet your specific needs offering safe, reliable operation for new construction, fuel system conversions and system upgrades including:

- Pressure Regulating Skids

- Flow Control & Metering Skids

- Single & Multiple Burner Systems

- Fuel Supply Safety Shut-offs

- Fuel Oil Systems Including:

- Fuel Oil Flow Control & Metering

- Atomizing Steam or Air Control

Equipment Design Features

- Wide Fuel Flow Capacity Rangers

- High & Low Pressure Reduction

- Service & Monitoring Design

- Pneumatic or Electric Actuation

- Material Selection

- Large Bore Trunnion Ball Valves

- High Performance Butterfly Valves

- Non-Hazardous & Hazardous Area Classifications

- DCS or Local Control Capability

- Fire Safe

Industry Standards

Fuel gas piping material and system design in compliance with applicable industry, local and/or international codes and standards:

- NFPA, API, NEC, FM, CSA, PED, ATEX, CE, NEMA, IP, etc.

- AWS Standard Welding Procedure

- B31.1 Power Piping

- B31.3 Process Piping

- Fire Safe Design/Construction

- Isolation Shut-Off Class VI

- Safety Interlocks

Custom Skid Mounted Equipment

Benefits

- Custom Design for Greater Flexibility

- Experienced In-House Engineering

- Manufactured to Local and International Codes and Standards

- Modular Pre-packaged Design

- Fully Assembled

- Factory Tested

- Process Guarantees

- Quality Control System (ISO 9001:2008)

- Established Service Network

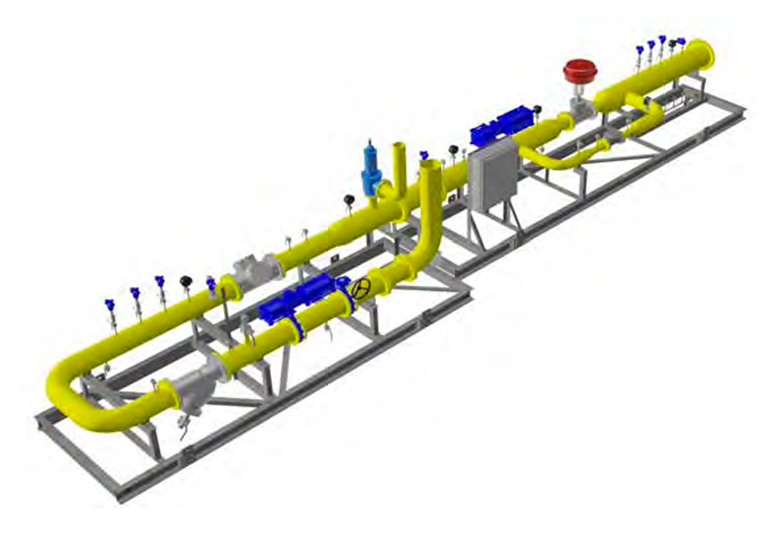

Natural Gas High Pressure Reducing Skid

Maximum flow: 1.2 MMSCFH

Turndown Ratio: 60:1

Pressure Reduction: 350 psig to 50 psig

Modular Designs for Fast Track Delivery

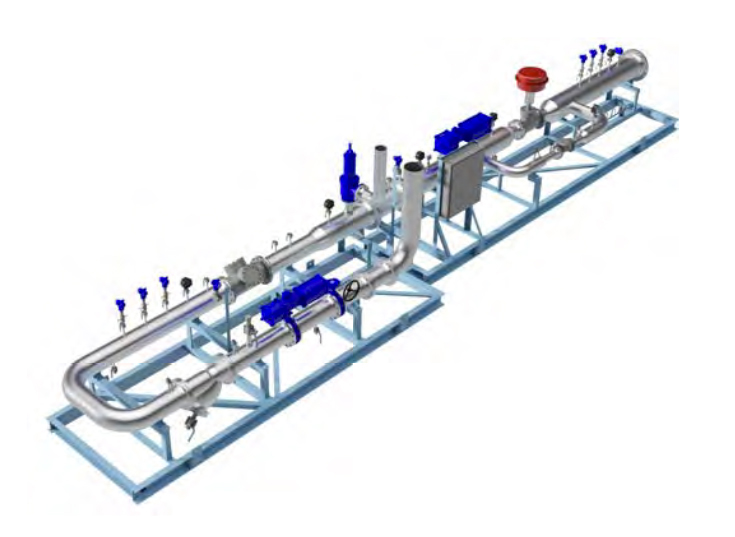

Natural Gas Control Skid

Maximum flow: 1.5 MMSCFH

Turndown Ratio: 70:1

Pressure Reduction: 100 psig to 25 psig

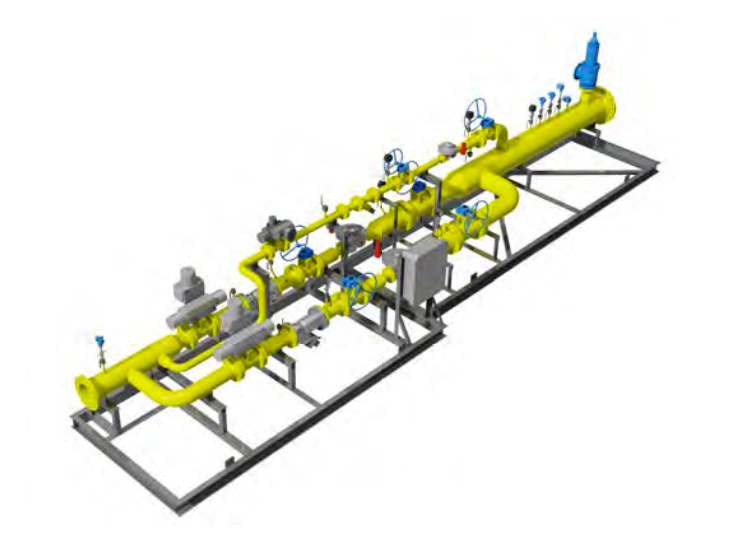

Natural Gas High Pressure Reducing Skid

Maximum flow: 4.4 MMSCFH

Turndown Ratio: 50:1

Pressure Reduction: 350 psig to 50 psig